Prefabricated modular solutions adapted for critical societal infrastructure

We deliver prefabricated, high-specification modular solutions, adapted for critical societal infrastructure.

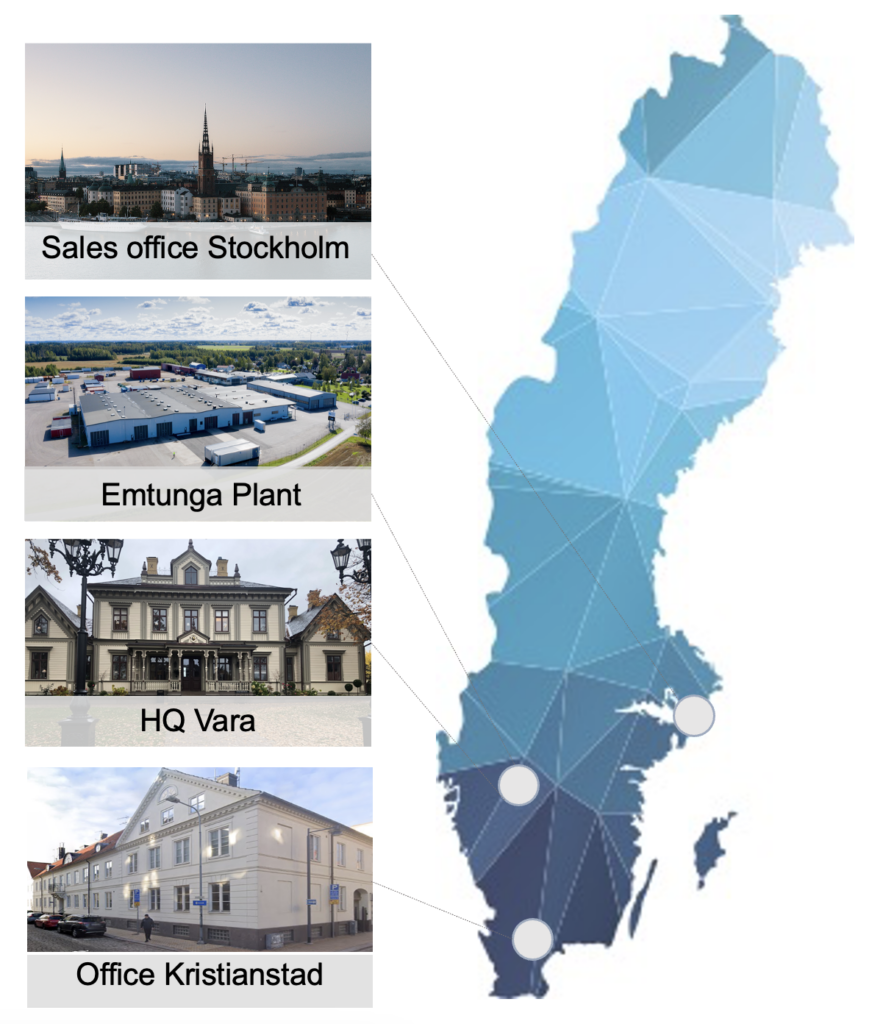

We design, engineer and produce products that are fully integrated with equipment tested and quality-assured in our partner’s production plant in Emtunga, Sweden. Our solutions are adapted for critical societal infrastructure, and we constantly strive to create greater function and value for our customers and their businesses. As a result, our portfolio is developed through an understanding of our customers’ businesses and needs.

Contact us to see how we can help you with a solution tailored to your business.

Swedish production – Global market

100%

Swedish production.

40+

More than 40 years’ experience in prefabricated modular solutions.

3500+

Over 3,500 high-specification modules.

30+

We have delivered to over 30 countries.

We deliver on demanding markets worldwide

For over 40 years, we have delivered prefabricated modular solutions from the production plant in Emtunga to demanding markets around the world.

We are capable of meeting stringent market requirements due to the expertise we have acquired over several years of delivering highly complex projects. This means we can assist our customers at an early stage with best practices, from design to delivery. During our 40-year history, we have delivered modules to over 30 different countries.

For over 40 years, we have delivered prefabricated modular solutions from the production plant in Emtunga to demanding markets around the world.

Our environmental and quality work

We are constantly working to improve the way we work and strive for the most environmentally friendly way of working.

Part of this is to find solutions that are gentler to the environment. It is a matter of course for us to be curious about ways to develop organization and production in the best sustainable way. The challenges are many but having the environmental aspect on the agenda every day, helps us stay focused and constantly develop our company.

Every year, our environmental and quality work must be reported and renewed with new goals for continuous improvement and continued sustainable development.

The production plant, which is run by our partner Swedish Modules KeyPlants AB, is ISO-certified according to ISO 9001: 2015 and ISO 14001:215, which shows that they also live up to concrete and recognized environmental requirements.

Among other things, they have introduced routines to optimize usage and not to consume more raw materials than necessary in the production process. During production, some waste also arises, which they constantly follow up and measure. In addition, the waste that is generated is sorted to minimize the waste that must go as a landfill.

Why you should use our solutions

A flexible solution for both permanent and temporary facilities.

Short delivery time compared to site-built. Up to 50 % reduction of delivery time, which enables faster access to capacity.

Minimal disturbance on-site – Sensitive existing operations experience minimal disruption due to a short time at the construction site (roughly five weeks).

Rent or buy depending on your needs; for example a temporary or permanent solution.

Sustainable solutions – Our prefabricated modules can be relocated, reused, renovated and adapted.

Industrial premium – Products designed to last. Robust steel construction that facilitates a high degree of prefabrication, an effective work environment, heavy process equipment and heavy lifting. Manufactured in a safe indoor environment in Sweden.

Risk mitigation – 95% of the construction work takes place in a production facility, which results in a ‘plug & play’ solution. This helps minimise risk in terms of schedule and budget.

Videos from our business

How we make a difference

Business Acumen

Long-term sustainable business for both our customers and us.

Relationship Builders

Always solution oriented with customer’s focus.

Transparency

Customer involvement and honesty in both internal and external communication.

Curious

We are studying trends and structures, and keep an open mind for change and development.

Swedish production

- Production performed in Emtunga, Sweden

- Large production facility that offers a high degree of scalability:

– 8.500 sqm indoor production area

– 50.000 sqm total outdoor production area - The location offers excellent transports with industrial ports (e.g. in Gothenburg and Uddevalla) and highway network in the proximity